An Unbiased View of Roar Solutions

( Area 0, 1, or 2). This variation will also influence the resourcing demands for work preparation. When Great deals are specified, you can create tasting strategies based on the example dimension of each Great deal, which describes the variety of random tools items to be checked. To determine the required example size, two aspects need to be evaluated: the size of the Whole lot and the group of evaluation, which suggests the level of effort that should be used( lowered, regular, or boosted )to the assessment of the Great deal. By integrating the category of inspection with the Lot size, you can then develop the proper denial standards for a sample, indicating the allowable number of damaged things discovered within that sample. For even more information on this process, please refer to the Power Institute Guidelines. The IEC 60079 common suggests that the maximum period in between assessments must not go beyond three years. EEHA inspections will certainly likewise be conducted beyond RBI campaigns as component of arranged maintenance and devices overhauls or repair services. These evaluations can be attributed toward the RBI example sizes within the influenced Great deals. EEHA inspections are carried out to identify mistakes in electrical tools. A heavy racking up system is necessary, as a single item of equipment might have multiple mistakes, each with varying degrees of ignition risk. If the mixed score of both examinations is less than two times the fault rating, the Lot is considered acceptable. If the Whole lot is still thought about undesirable, it should undertake a full evaluation or validation, which may activate more stringent inspection procedures. Accepted Whole lot: The causes of any type of mistakes are identified. If a common failing setting is discovered, added equipment may call for maintenance. Mistakes are identified by severity( Safety and security, Stability, Home cleaning ), guaranteeing that urgent problems are examined and resolved promptly to reduce any type of effect on safety and security or procedures. The EEHA data source should track and tape-record the lifecycle of faults together with the rehabilitative activities taken. Executing a durable Risk-Based Examination( RBI )technique is essential for making certain compliance and security in managing Electrical Equipment in Hazardous Areas( EEHA). Automated Fault Scoring and Lifecycle Management: Effortlessly handle faults and track their lifecycle to improve evaluation accuracy. The introduction of this support for risk-based inspection further strengthens Inspectivity's placement as a best-in-class solution for governing conformity, in addition to for any type of asset-centric evaluation use case. If you have an interest in discovering more, we welcome you to request a presentation and discover how our remedy can change your EEHA administration processes.

With over 10 years of mixed Ex experience (IECEx/ATEX, EEHA), Saipex began to promote the value of competence of all workers involved in the Hazardous Location area in 2019. In 2021, our collaboration with IndEx and Tech Ability International (TSI) marked a milestone in the Saipex road to continue Ex lover improvement.

The Only Guide to Roar Solutions

In terms of explosive danger, a dangerous location is an atmosphere in which an eruptive atmosphere is present (or might be expected to be present) in quantities that call for special preventative measures for the building, installment and use of tools. In this article we check out the difficulties dealt with in the work environment, the danger control procedures, and the required proficiencies to function safely.

It is a repercussion of modern life that we produce, store or take care of an array of gases or liquids that are regarded flammable, and an array of dusts that are regarded combustible. high voltage courses. These compounds can, in certain conditions, create explosive ambiences and these can have significant and unfortunate repercussions. Many of us are familiar with the fire triangular remove any type of among the three aspects and the fire can not take place, however what does this mean in the context of unsafe areas? When damaging this down right into its simplest terms it is basically: a mix of a certain quantity of launch or leakage of a particular compound or product, mixing with ambient oxygen, and the existence of a resource of ignition.

This is then verified through assessment and testing and is protected throughout the life of the installment by employing the proper maintenance techniques, supplemented by periodic assessment. When all these measures are taken, they must additionally be documented. The confirmation file includes details such as the hazardous area category illustration, suppliers' documentation, devices qualification, design drawings and computations, examination records, and documents of an individual's proficiency and proceeding professional development (CPD), such as using ECA's eCOMS software application.

The Basic Principles Of Roar Solutions

It is essential that trainees recognize and have an extensive expertise as to exactly what comprises a hazardous area. The trainee must additionally recognize why training is necessary prior to trying to take on work or specifying devices right into a hazardous area. These areas are likewise referred to as classified places and are defined as locations which have a high chance of an explosion as a result of the possible existence of flammable gases, vapors, dusts etc.

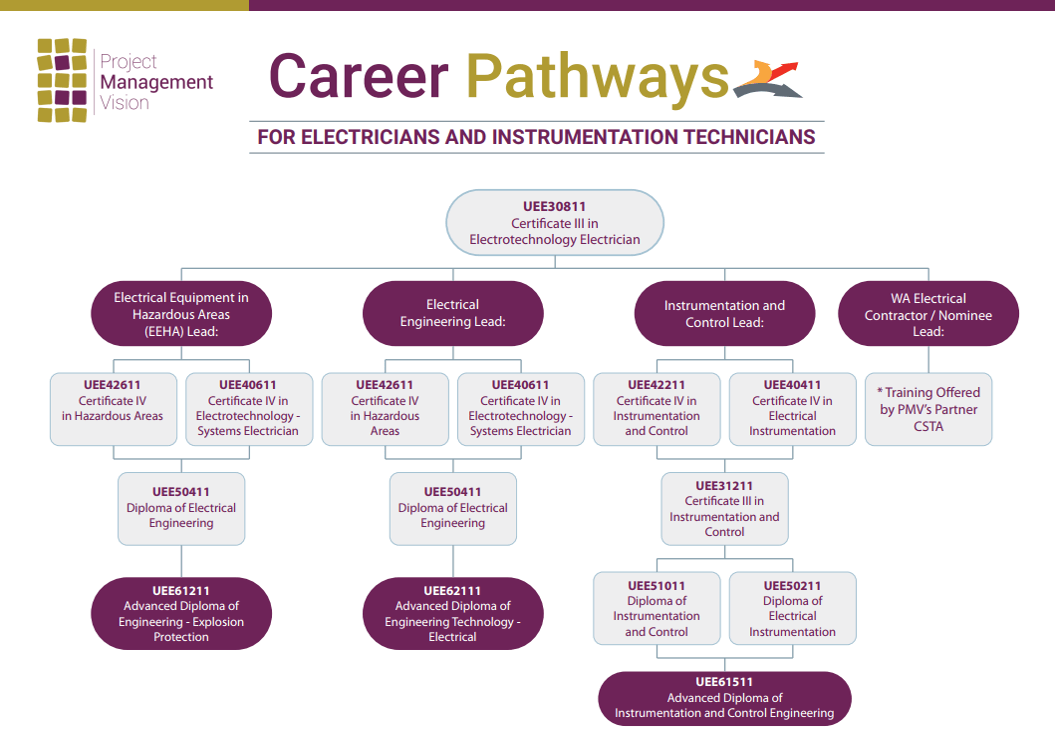

Industries that have hazardous areas are now requiring that electric employees that are defining or functioning in these locations must have a harmful location credentials that regards them skilled. Jobs in these industries are very rewarding so you need to be prepared. To meet this need for the sector, nationally recognised training in Certificate IV in Hazardous area Electric and EEHA training on the growth of experienced professionals.

Our Roar Solutions PDFs

Tech Skills Australia is a Registered Training Company giving you with the most cost effective and quickest means in acquiring your certification - eeha courses. Our trainers are market qualified and have a number of years of process experience. Our training courses have helped thousands of people from company supervisors to daily workers in acquiring a solid hang on this not so difficult yet high danger training

The training likewise includes identifying the hazardous locations, resources of explosion and the residential or commercial properties of dangerous materials in addition to the duties and features of all parties, regulations, systems, criteria and method codes connected to hazardous locations. We supply instrumentation and dangerous location options that are in conformity to most recent AS/NZS and worldwide industry standards.

Comments on “Everything about Roar Solutions”